A hopback allows you to hop your brew just before cooling it. The advantages here are, of course, the ability to add hop flavor, without adding bitterness. This is a somewhat similar result to dry-hopping.

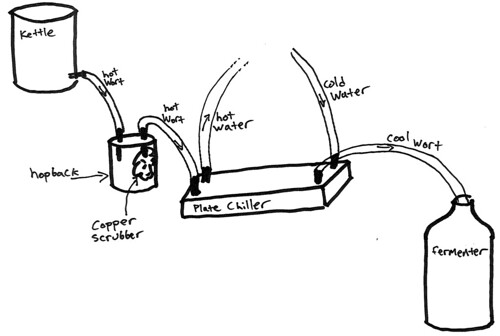

I decided to build a hopback when I bought a plate chiller. I was dissatisfied with my immersion chiller, which I felt took to long to cool the wort. So, I bought a plate chiller, which is a smaller version of what the big breweries use. Basically, you have cold water running between copper plates counterflow to your wort.

When I was doing some research about plate chillers, I found that it was good to put a hopback in the line before them, after your brew kettle. This will keep the hop solids and hot break from clogging the plate chiller.

I found a couple of websites explaining how to make a hop back, so I read them , got some ideas, and then made my own. Here are my notes on how I made mine.

[ad]

My concept is based on this idea, where

you push the boiling hot wort into a Mason jar filled with hop plugs, and then, when the jar fills up with wort, the wort is let out through another tube, which leads to the plate chiller.

you push the boiling hot wort into a Mason jar filled with hop plugs, and then, when the jar fills up with wort, the wort is let out through another tube, which leads to the plate chiller.

I started with a Mason jar, and I used a large bore drill bit to drill a hole in it. I needed to make a hole big enough to fit my brass fitting for my tubing. So, I made a big hole, and the drill bit made lots of burrs. It was a mess.

I bought another mason jar, and drilled the holes more carefully. I then tried to solder the brass fitting on with a blowtorch and silver plumbers’ solder. I figured silver plumbers’ solder would be appropriate, since if it’s good enough for drinking water, its good enough for beer. What I wasn’t counting on was the plastic gasket coating on the bottom of the mason jar lid melting. So, I went back to the hardware store, and bought another Mason jar.

Finally, I decided to trace the outline of my brass fitting with a Sharpie marker, and cut the holes out with an Xacto knife. Bingo. I got just the size holes I needed, with no burrs.

Instead of soldering, I used rubber washers as gaskets, and screwed the brass fittings on. I just bought some rubber washers from the local hardware store, so I don’t know if they were food-grade of anything, but I ran some hot water through it when I finished, and, of course, I run sanitizer though the whole set up whenever I use it.

After I set everything up, I hooked up my hoses, and tried to run some hot water through it.

Lo and behold, all of the connections leaked. I then put some Teflon pipe thread tape on the connections, and tried again. That seemed to do the trick.

So, Teflon was the answer. Since then, I’ve made a few brews with this setup, and everything seems to go well.

Below is a photo of my whole setup, with Idophor sanitizer running through it, before I made my APA/Hefeweizen hybrid brew.

I have also made an Apple Ale with this setup, and it works great. I have to say, as much fun as it is creating new homebrew equipment, it is much more fun using it, and having it work.

A brew buddy and I actually spent a whole day working out the logistics of this contraption, and we had to delay brewing. When I actually brewed with it, and saw the 200o+ wort flowing in, and the ~65o F wort flowing out of the chiller, it was all worth it.

When I tasted the beer, it was really worth it.

I use the hopback on every brew, even if I’m not making a hoppy beer. In that case, I will just leave the hops out, and use the hopback as a sort-of filter to trap any sediment before the wort flows into my plate chiller. Below is a diagram of how the whole thing goes together.

2 Comments